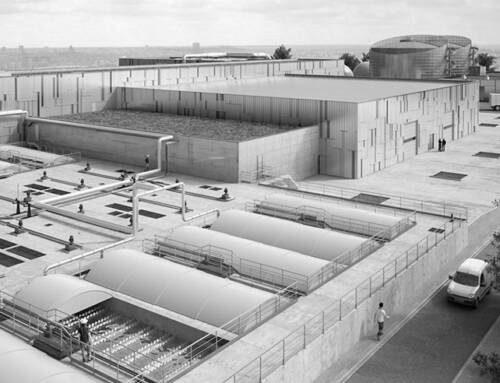

Bakou Incineration Plant, Azerbaijan

The Bakou incineration plant located in Azerbaijan is operated by CNIM AZ. CNIM AZ is also the engineering company that designed and financed the construction of the plant. The investment for this incinerator amounts to 346 million euros.

Initiated by the President of the Republic of Azerbaijan in 2006, the project is part of a series of measures taken by the government to promote the environment. Under the supervision of the Ministry of Economic Development, the state-owned company Tamiz Shahar JSC, responsible for waste management in Bakou, entrusted CNIM with the design, construction, and operation of an energy recovery center for 20 years.

This flagship project, spanning 10 hectares, is one of the largest facilities ever built in Azerbaijan. The plant, which started operating in 2012, consists of two lines capable of incinerating 500,000 tons of waste per year and producing 231 GWh/year of electricity.

ENNOVIA‘s Missions

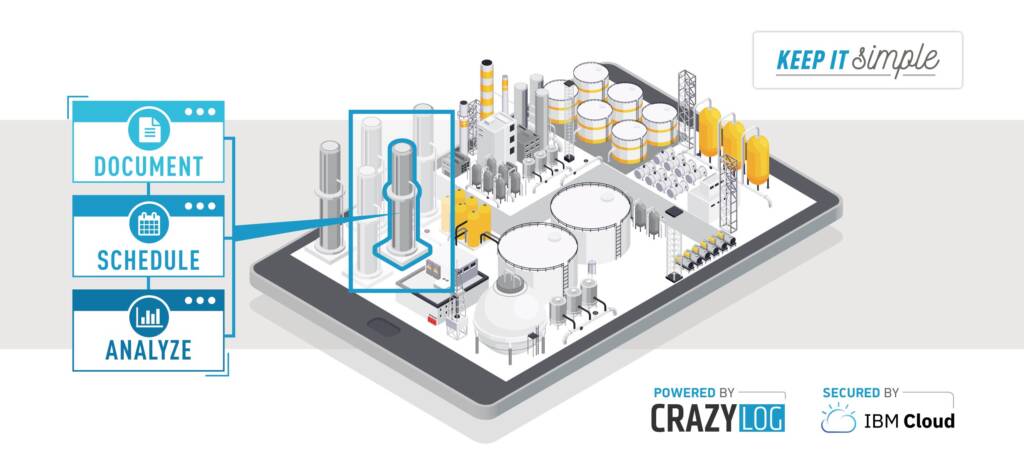

ENNOVIA was responsible for providing maintenance engineering services and implementing the Quickbrain CMMS for the entire site.

For your information, Quickbrain replaced the COSWIN CMMS (SIVECO) that was considered too complex by the operator.

Furthermore, the plant employs approximately 120 people for operations and maintenance.

Maintenance Engineering Phase

- Build the functional and technical hierarchy of the site

- Analyze equipment criticality

- Create and optimize the maintenance plan

- Create and optimize the spare parts list

- Integrate all technical documentation of the site

Quickbrain CMMS Integration Phase

- Draft functional and technical specifications

- Provide licenses

- Establish a hosted IT infrastructure (IBM Bluemix cloud)

- Install and make the application available

- Configure the application

- Populate the application with data generated during the maintenance engineering phase

- Provide personnel training

- Implement performance indicators

ENNOVIA provides a unique end-to-end service to deliver a turnkey CMMS solution to the end client, in collaboration with their teams and those of the engineering company (CNIM).

The CMMS was put into operation immediately upon the plant’s reception.

CLIENT TESTIMONIAL

“We have been collaborating with ENNOVIA for 5 years now, and we have truly appreciated their knowledge of maintenance, professionalism, and ability to meet our expectations. The Quickbrain software has allowed us to optimize the management of our preventive maintenance and stocks thanks to its simplicity and continuous evolution of its functionalities. The ENNOVIA support is flawless and always responds to our requests, often going above and beyond.”