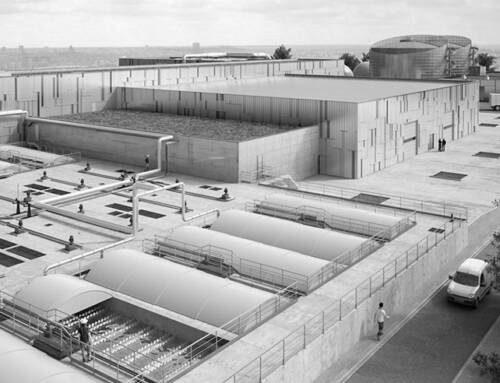

La Collette Incineration Plant, Jersey

Equipped with a thirty-year-old, inefficient, and costly incineration plant, the States of Jersey chose to invest in a new, state-of-the-art, and larger capacity waste-to-energy facility in 2011.

The construction of this incinerator represents an investment of approximately 150 million euros.

The La Collette plant consists of two lines capable of incinerating 105,000 tons of waste per year and generating 82 GWh/year of electricity.

ENNOVIA‘s Missions

ENNOVIA was selected to provide maintenance engineering services and implement the Quickbrain CMMS system on-site.

The plant employs approximately 40 people for operations and maintenance.

Maintenance Engineering Phase

- Build the functional and technical hierarchy of the site

- Identify critical equipment based on the plant’s failure history and equipment criticality

- Develop and optimize the maintenance plan

- Create and optimize the spare parts list

- Integrate all site documentation

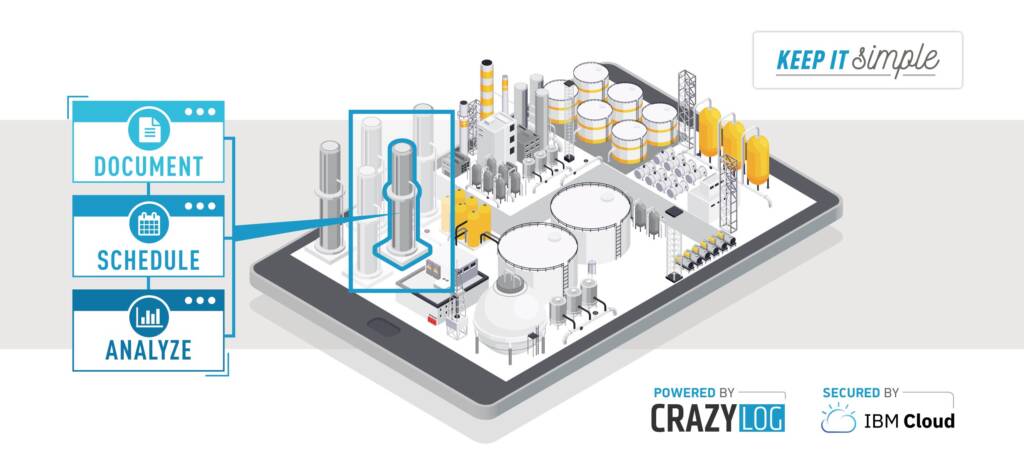

Quickbrain CMMS Integration Phase

- Draft functional and technical specifications

- Provide licenses

- Establish a hosted IT infrastructure (IBM Bluemix cloud)

- Install and make the application available

- Configure the application

- Populate the application with data generated during the maintenance engineering phase

- Provide personnel training

- Implement reporting and performance indicators

ENNOVIA knows how to work in synergy with maintenance teams and deliver results rather than just a number of days. All our services are fixed-price, and we are fully involved in the CMMS implementation process. Not just as a tool but as part of an overall maintenance process.

CLIENT TESTIMONIAL

“As an independent operator, we had studied a lot of potential solutions for implementing a CMMS. We have selected Quickbrain because of its flexibility, simplicity, and perfect fit with the requirements of our maintenance team. Moreover, the software implementation, supported by ENNOVIA maintenance experts, is seamless. The final goal was to increase our performance and reduce our downtime, which is why we have chosen a maintenance service company instead of a pure software vendor.”